Written by Christopher Barrett, ’08

To understand the role of plastics in our world, imaging equipment housed within the University of Rhode Island’s (URI) core facilities analyze plastic particles so small that it would be like finding a single drop of water in an Olympic- sized pool.

Scientists leverage that data to trace plastics pollution in waterways to its source, to understand how plastic particles harm animals, as well as to develop nanoplastics that deliver life-saving medicines into our bodies.

“People are looking at microplastics in a lot of different areas; they are popping up everywhere and we don’t know if they’re good, bad or neutral,” said Rhode Island Consortium of Nanoscience and Nanotechnology Director Irene Andreu.

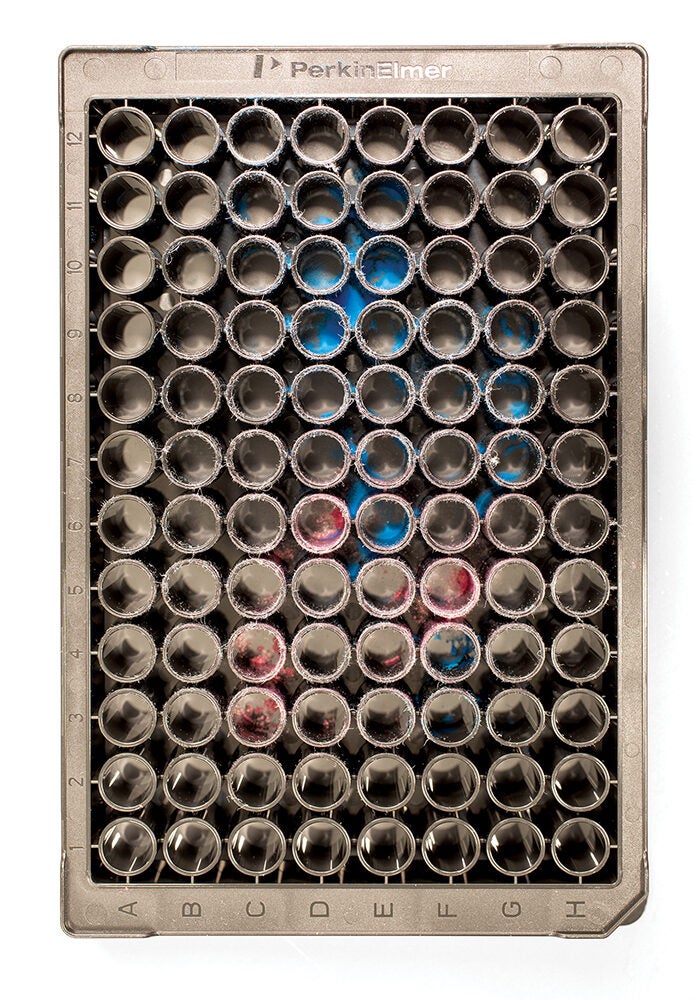

Yet, looking at micro and nanoplastics poses significant challenges. Plastics comprise a wide variety of polymers with additives to change their texture, rigidity and color. When plastics break apart, the material leaves a trail of pieces often visible only with specialized equipment. That’s where the University’s core facilities and their researchers step in with equipment and expertise.

To encourage cross pollination of plastics research, the University’s Division of Research and Economic Development this year assembled the research groups and facilities that support plastics research under a strategic research initiative. The network also positions the institution to win research grants by fusing

expertise, said Kathleen Shannon, who oversees strategic initiatives for the research division.

“People need to understand core facilities and how important they are to collaboration, innovation and science,” Shannon said. “For people to find collaboration and innovation and advance science they need a place, and they need equipment.”

Conveniently, people don’t have to look any farther than the University of Rhode Island campus.

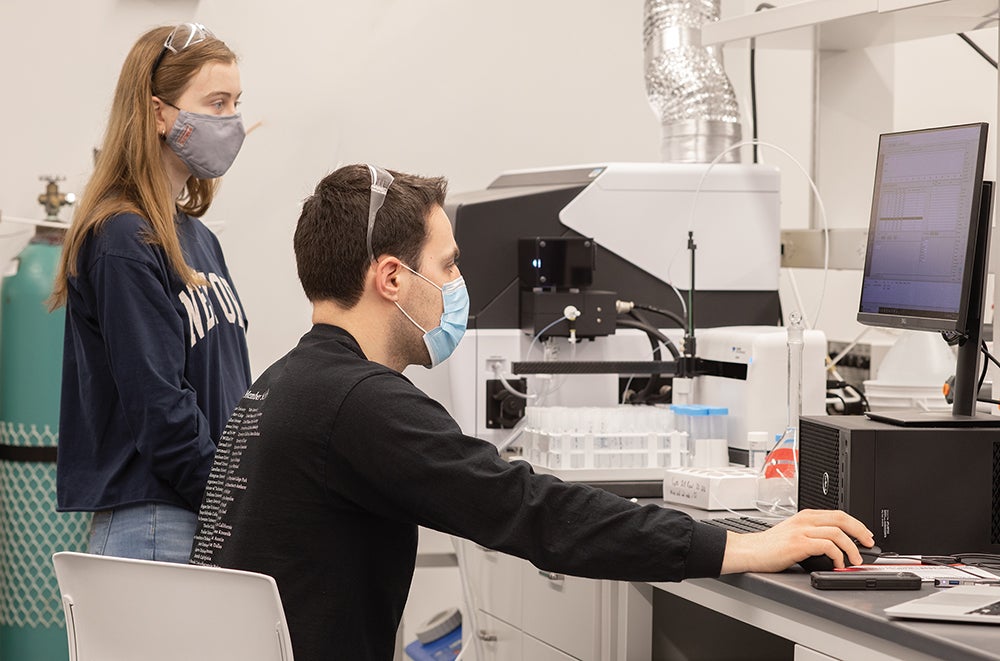

Scanning electron microscopes in the University’s facilities detect objects around 1,000 times smaller than those visible through a typical high school lab optical microscope. The fluorescence microscopes emit high-intensity light and measure the light reflected rather than absorbed by the sample to see details not possible with a traditional microscope. The Raman microscope shoots lasers at a sample to differentiate types of plastics at the sub-micrometer level.

The centralized list of equipment and expertise opens the door for industry partnerships. Especially for startups, accessing the equipment available at the University would otherwise prove cost-prohibitive

Left: Vinka Oyanadel-Craver, Professor, Civil and Environmental Engineering

The mass spectrometers bombard electrons at molecules in a sample and measure the resulting mass-to-charge ratio to identify unknown compounds. The X-ray diffractometer uses radiation to analyze the structure of materials. The high-pressure liquid chromatography equipment sends samples through a column with absorbent materials that cause different components to separate leading to their identification.

Some of the individual pieces of equipment cost upwards of $4 million, making these instruments impractical for a single researcher to acquire and maintain. The core facilities acquired much of their equipment through a mix of institutional investments, grants and donations, including $2.8 million from the National Science Foundation and a six-figure gift by Shimadzu Corp., a Japanese manufacturer of scientific equipment. Much of the equipment resides in the $150 million Fascitelli Center for Advanced Engineering where the glass walls literally showcase research and invite collaboration.

Inside the core facilities, the equipment empowers researchers to detect specific shapes and additives that offer clues to a plastic particle’s origins: perhaps a plastic shopping bag thrown into the ocean by a careless customer or a damaged PVC pipeline.

With that information, scientists and policymakers can institute steps to halt pollution at its source, a task much easier than attempting to remediate an already polluted environment. That ability is important to people like civil and environmental engineering Professor Vinka Oyanedel-Craver, who recognizes the risk of plastics overrunning the ecosystem. The tools in the core analytical lab she helps to manage allow her and many other researchers at URI to tackle the issue like never before.

“It is really exciting to have all this equipment,” Oyanedel-Craver said. “These tools provide an amazing level of detail.”

Other labs and programs around campus assist in obtaining the samples for analysis. The URI Diving Research and Safety Program offers equipment and training for those looking to collect water samples whether from Narragansett Bay or waters halfway around the world. The samples return to campus for analysis. Lately, researchers have been particularly interested in analyzing water for plastics pollution that poses a threat to wildlife and human health.

“We have a united front so it’s easy for an industry person coming from the outside. It’s one- stop shopping”

Right: Carol Thornber, Professor, Natural Resources Science & Director, University Research Operations

The diving program is also collaborating closely with a non-profit foundation that is in residence on URI’s Narragansett Bay Campus, The Ocean Agency, to develop novel underwater photography systems for high-resolution 3D mapping of fragile ecosystems.

For those looking to skip the travel, the Seawater Facilities on the Narragansett Bay Campus literally pump in seawater to replicate any marine environmental condition. The Marine Science Research Facility offers space for scientists to prepare samples, analyze DNA, and assists with designing experiments.

Natural resources science Professor Carol Thornber recognized early on the economics of scale and research potential of formalizing connections among the labs. She’s now leading that charge as part of her leadership role within the research division.

“Science over the past few decades has become more and more of a collaborative process,” Thornber said. “I can solve one piece of the puzzle and another researcher can solve the other.”

Thornber said the big picture view positions researchers to spend less time on administrative tasks and more time on science. And the centralized list of equipment and expertise opens the door for industry partnerships. Especially for startups, accessing the equipment available at the University would otherwise prove cost prohibitive.

“We have a united front so it’s easy for an industry person coming from the outside. It’s one- stop shopping,” Thornber said.

The equipment also sets up students for success in their future careers. Oyanedel-Craver said there is more than learning how to use a microscope or other imaging equipment. While one person operates the equipment, there might be dozens or even hundreds of people — engineers, programmers, chemists and physicists, among others — involved in analyzing the results for meaningful discoveries.

URI students, Oyanedel-Craver said, sit at the unique crossroads where they can collect a sample, analyze it at the nano level and interpret the results without ever leaving campus. And in studying samples sent by vendors, students often detect subtle differences between the sample’s claimed material composition and what arrived in the box. Vendors often confirm that these minute differences are within the promised tolerances that most people never notice because they lack access to the sophisticated labs.

“It’s very cool what we can measure,” Oyanedel- Craver said. “It’s the best equipment you can have.”