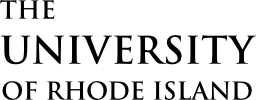

Saleh Allababidi prepares Rhody Blue hand sanitizer. Allababidi is shown wearing a beard covering as required for this production. This photo was shot prior to PDI requiring respirator masks.

University of Rhode Island faculty and staff are part of a growing number of volunteer researchers, scholars, medical professionals, industry leaders, and makers assisting the state of Rhode Island in the battle against COVID-19.

URI’s effort involves multiple colleges and departments. Researchers are creating hand sanitizer, making parts for first responders’ personal protective equipment, PPE, and collecting lab supplies for use in treating patients.

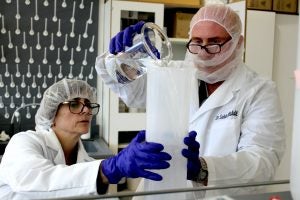

Aiming to address a local shortage of hand sanitizer, scientists in the URI Pharmaceutical Development Institute have begun production of the hand sanitizers Rhody Blue and Rhody Clear. Made in the College of Pharmacy’s labs, both hand sanitizers contain 75% isopropyl alcohol. Rhody Blue is being used by public safety staff on campus and has been distributed to health care workers, free clinics, and other external groups. Rhody Clear is being produced for the state Department of Corrections. The effort is being led by Saleh Allababidi, URI Pharmaceutical Development Institute senior development scientist and faculty member.

Rapid Response

Kunal Mankodiya, associate professor, electrical, computer, and biomedical engineering at URI’s College of Engineering, facilitated the creation of the group Rapid Responders. Mankodiya and two other URI faculty members had the idea to marshal their efforts during a discussion about ventilator designs, face shields, and the challenges of making N95 respirators and surgical masks. Within 48 hours they had 15 members. Now 72 members strong, Rapid Responders includes members from other state colleges and universities, as well as medical professionals, private businesses and specialists in 3-D printing.

The group holds virtual meetings every couple of days, sharing information ranging from global trends they’re following to 3-D files for face shields and tips on purchasing the elastic needed for face masks, which has become a scarce commodity in recent weeks.

“We all were looking at what was happening in Italy, and we started to see cases increasing in the United States,” Mankodiya said. “We were getting emails from the state asking, ‘Can you help with your expertise?’

A time to collaborate

“As soon as we became centralized, people were ready to help in so many different ways. Less than five days after we started, we had a whole community of 3-D printer experts ready to help,” he continued. “This is the time to talk regularly.”

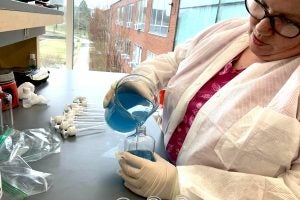

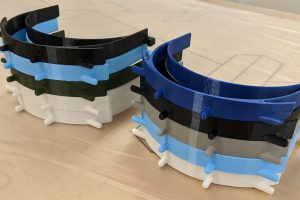

Rapid Responder member Erika Uzmann, scholarly technology lab manager at URI Libraries, is overseeing the production of plastic bands for face shields using the University’s 3-D printers. A face shield is a transparent plastic barrier that sits over the N95 surgical mask, protecting it. The bands are worn across the forehead and hold the shield in place. Because of the materials used in their manufacturing, the face shields prolong the use of other PPEs and can be cleaned and reused.

‘Any contribution has impact’

Makerspace URI has six 3-D printers, a laser cutter, two VR headsets, a 3-D scanner, two vinyl cutters, a sewing machine, and a digital embroidery sewing machine. The space is usually used by engineering students for prototyping designs and testing ideas and concepts, Uzmann said. At present, the maker space printers are making 12 bands a day. Each band takes about four hours to print.

“Medical professionals need as many supplies as they can get,” Uzmann said. “So any contribution we can make has impact. It’s great to be able to help something along.”

Rapid Responder member Brennan Phillips, assistant professor, ocean engineering, is working on the designing of equipment to be used in ventilators. “Right now, it’s face shields that are being made and delivered, but there are prototype face masks in development. And, we’re working with doctors and respiratory specialists at several hospitals around the state to design and fabricate prototype tubing that is used with ventilators.”

Rapid Responder member Roxanne Beinart, assistant professor of oceanography at URI’s Graduate School of Oceanography, received an email from Peter Snyder, vice president for Research and Economic Development and professor of biomedical sciences. It was an all-call of sorts for supplies. Beinart put together cases of swabs and gloves and, along with other URI labs, donated those to the Rhode Island Department of Health.

“I’m happy to devote my time to doing this,” Beinart said.

Coming together in record time

A COVID-19 testing center for pre-screened patients has been established in the Plains Road parking lot on the Kingston campus. A 3-D printer center is planned for The Fascitelli Center for Advanced Engineering at the Kingston campus.

A private company that joined Rapid Responders is taking the lead on researching the FDA approval process, Mankodiya said. In a time of unprecedented uncertainty, Mankodiya said the efforts of so many hearten him.

“I have never seen something like this come together in such a short time,” he said. “Never in my life. It’s mind-boggling.”