KINGSTON, R.I. – April 30, 2020 – With Rhode Island experiencing its highest numbers of COVID-19 cases to date, there is a greater need than ever for personal protective equipment (PPE), including face shields.

About a dozen students at the University of Rhode Island are among the many people who have volunteered their time to fabricate face shields for police officers, firefighters, emergency medical services personnel, doctors, nurses and other health professionals.

Rather than return to their hometowns once remote learning went into effect, these URI students and volunteers have remained on campus to produce protection equipment for Rhode Island’s front-line responders.

“When the opportunity came up to help the doctors and nurses who put their lives on the line to save others, I had to do my best to offer my support with the resources I have,” said Victor Chung, a biomedical engineering student from Waltham, Massachusetts.

Chung spends 5 to 7 hours a day in the 3-D printer center that has been set up in the biomedical engineering capstone laboratory in URI’s Fascitelli Center for Advanced Engineering. The senior ensures that all the prints run smoothly from the printers.

According to technician Tanya Wang, who oversees the printer center, the College of Engineering has produced more than 2,000 face shields, at a rate of 100 per day.

Dominik Brysch, who has been studying industrial engineering at URI through the International Engineering Program’s partnership with Technical University Braunschweig in Germany, was eager to help.

“As an industrial engineer, I don’t have the skills to make people healthy again, but I can do my best to develop something to protect them from getting sick in the first place,” said Brysch, who is from Saarbücken, Germany.

Brysch will receive his master’s degree from URI in industrial and systems engineering in August.

Afnan Altekreeti, a sophomore in URI’s biomedical engineering program, found out about the opportunity to volunteer from Chung.

“Since I’m familiar with the 3-D printing process and it was a chance to help the people in the health care field, I was glad to participate,” said Altekreeti, a Warwick, Rhode Island resident.

Altekreeti volunteers twice a week for 3 to 4 hours a day. She’s available to put more time in, but the group has been abiding by Rhode Island’s rules for social distancing.

“We don’t want to have more than three or four people in the lab at the same time and we try to keep our distance,” stated Altekreeti.

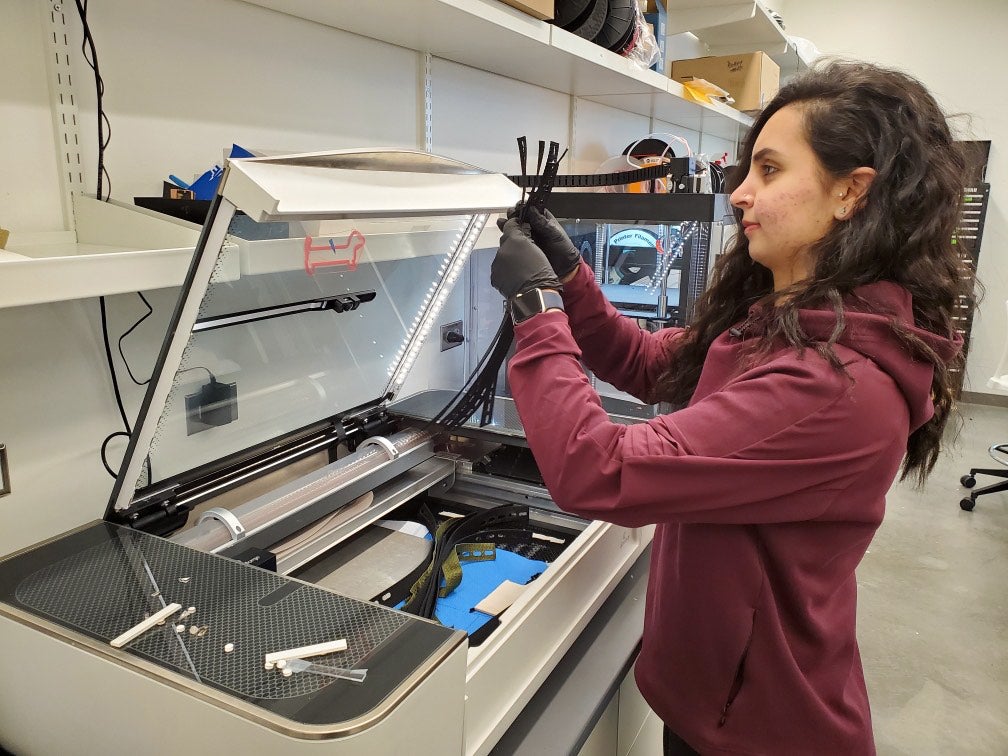

While the plastic bands are printed at the Fascitelli Center, the clear plastic part of the shields is produced in one of the engineering labs at URI’s Narragansett Bay Campus.

A Universal Laser Systems printer is used to cut cellulose plastic into sheets for the masks.

“It takes about 8 to 10 minutes to cut a single sheet with three shields on it,” said Nicholas Chaloux, a senior ocean engineering student from Newtown, Connecticut. “For every 32 inches of a 42-inch-wide roll of material, we can make 12 shields.”

Chaloux estimated that he spends 5 or 6 hours per day cutting the clear sheets. Once a batch is cut, someone from the Bay Campus brings them to the Fascitelli Center where they are assembled with the other parts of the shields.